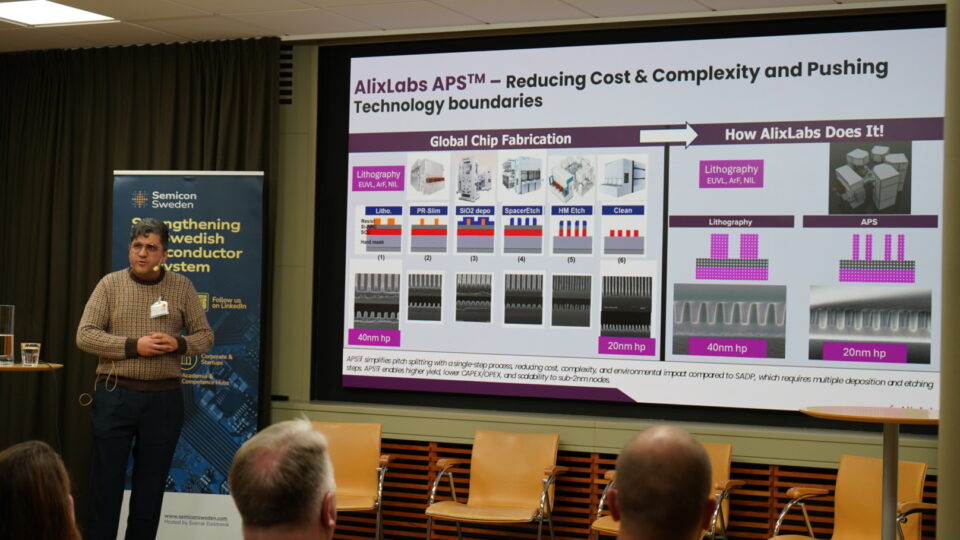

New automation platform paves way for fully automated, fab-ready solution for the company’s innovative, cost-effective and sustainable pitch splitting technology.

Lund, Sweden – November 4, 2025 – AlixLabs AB today announced the arrival and installation of the Brooks Automation Marathon 2™ LEAP platform and MagnaTran® LEAP™ vacuum robot, key components for the company’s upcoming APS™ 300 mm Beta platform. This milestone marks a major step toward full automation of AlixLabs’ Atomic Layer Etch Pitch Splitting (APS™) process technology and paves the way for 24/7 wafer processing and qualification with leading semiconductor manufacturers.

The Marathon 2™ Compact 500 provides a fully integrated, clean, and reliable front-end platform for 300 mm wafer handling. Designed to support both standard wafers and film frames, it is ideally suited for advanced front-end and packaging applications. Combined with the proven MagnaTran® LEAP™ vacuum robot, the platform ensures precise, particle-free wafer transfers, improving throughput, yield, and uptime. The system benefits from Brooks Automation’s extensive global install base, ensuring reliability and compatibility with leading-edge fabs worldwide.

Complementing the Brooks solution, Kontron AIS and its Tool Commander® software provide the automation backbone for AlixLabs’ APS platform. Tool Commander® offers a standardized and modular control architecture that enables seamless integration of process modules, robotics, and fab automation systems. Fully compliant with SECS/GEM and EDA standards, it supports Industry 4.0 and smart manufacturing, allowing AlixLabs to deliver a fully automated, fab-ready solution.

Why It Matters

With this installation, AlixLabs is now equipped to qualify APS™ and commence Beta testing with leading integrated device manufacturers (IDMs) and foundries. Test and product wafers can be processed in Lund and returned to customers for metrology and electrical verification, validating APS™ performance in real manufacturing environments.

This new fully automated platform enables round-the-clock operation and significantly cleaner wafer handling, representing a major leap forward from AlixLabs’ earlier semi-automated system. As a result, the company will double its demonstration capacity and strengthen its position as a solution provider ready to commercialize APS™ into the global semiconductor market.

Comments

“This milestone marks a critical step in transforming APS™ from a research innovation into a production-ready technology,” said Jonas Sundqvist, CEO of AlixLabs. “By combining Brooks’ industry-proven wafer handling with Kontron AIS automation, we are now positioned to demonstrate APS™ at full 300 mm scale – enabling our customers to validate the technology in conditions that match their own fabs.”

What’s Next

In the second half of 2026, AlixLabs plans to install additional APS™ chambers featuring a completely new design optimized for high-volume manufacturing (HVM) on the Brooks Automation platform.

Additional Pictures